Switching power supply

- History

- Core technology

- Safety standards/surveys

- Features

- Power supply technology

- Quotation/development process

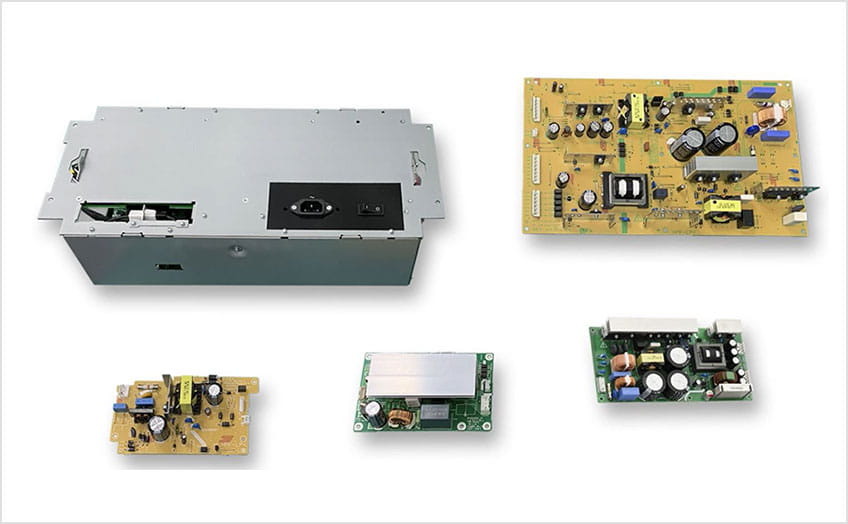

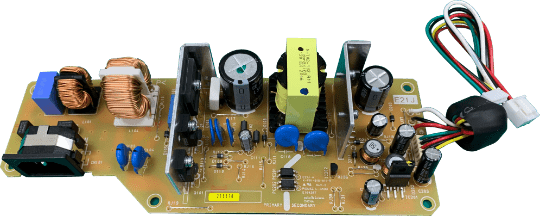

- Product lineup

- Network

- Inquiry

History of Nichicon Switching Power Supplies

Backed by our proven track record in low-voltage power supplies and high-voltage power supplies, we have created innovative products that satisfy our customers for various market applications and product applications, including office equipment power supplies. We also strive to ensure safety and maintain high levels of quality, and in 2020, we became No. 1 in terms of market share in the custom power supply field for Japanese power supply manufacturers.

(Source: EMJ Co., Ltd. “Switching Power Supply/DC Stabilized Power Supply-Survey Report-“)

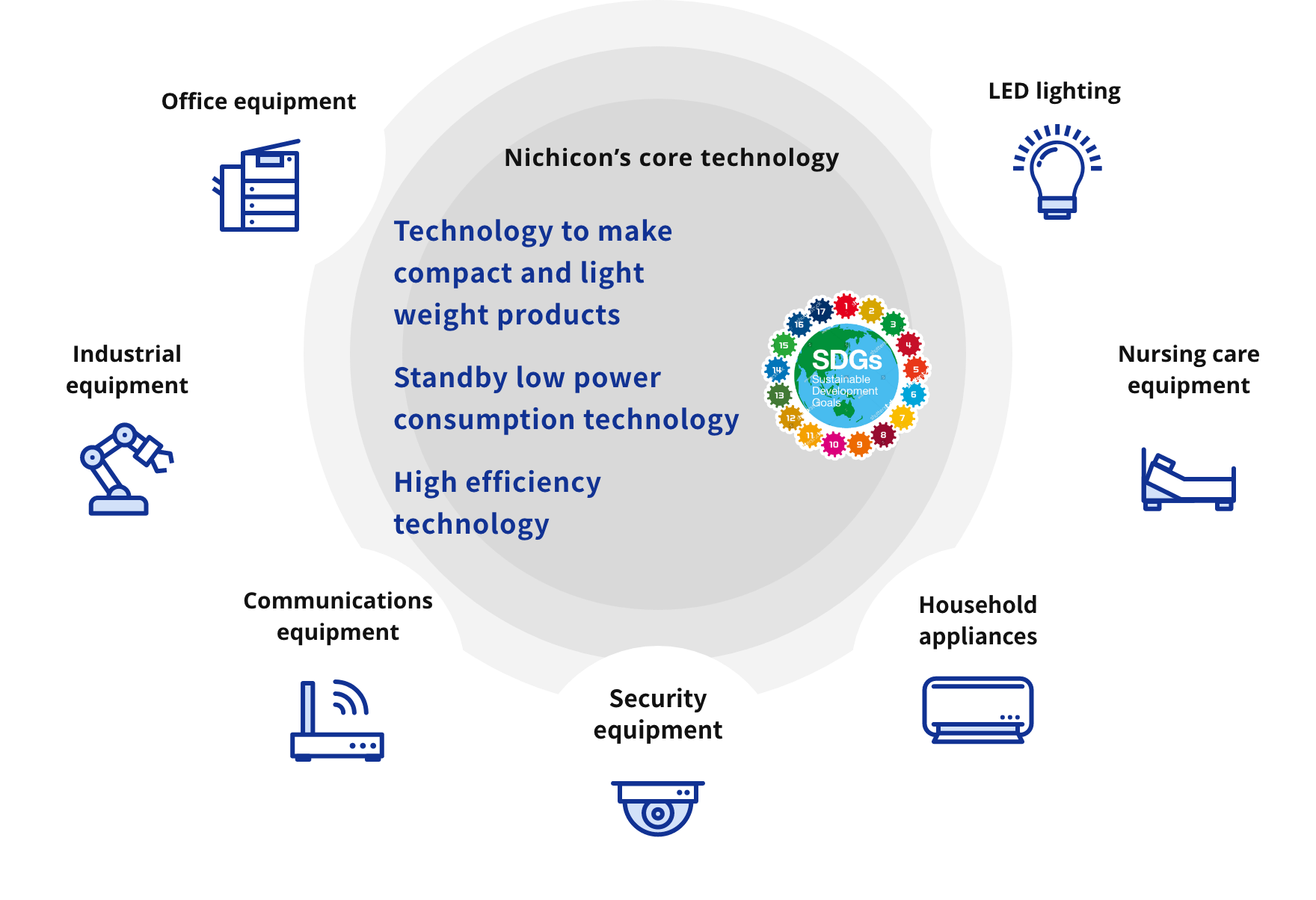

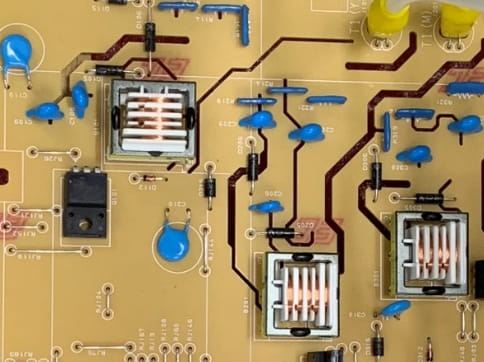

Nichicon’s core technology

We offer switching power supplies with custom specifications according to customer requirements.

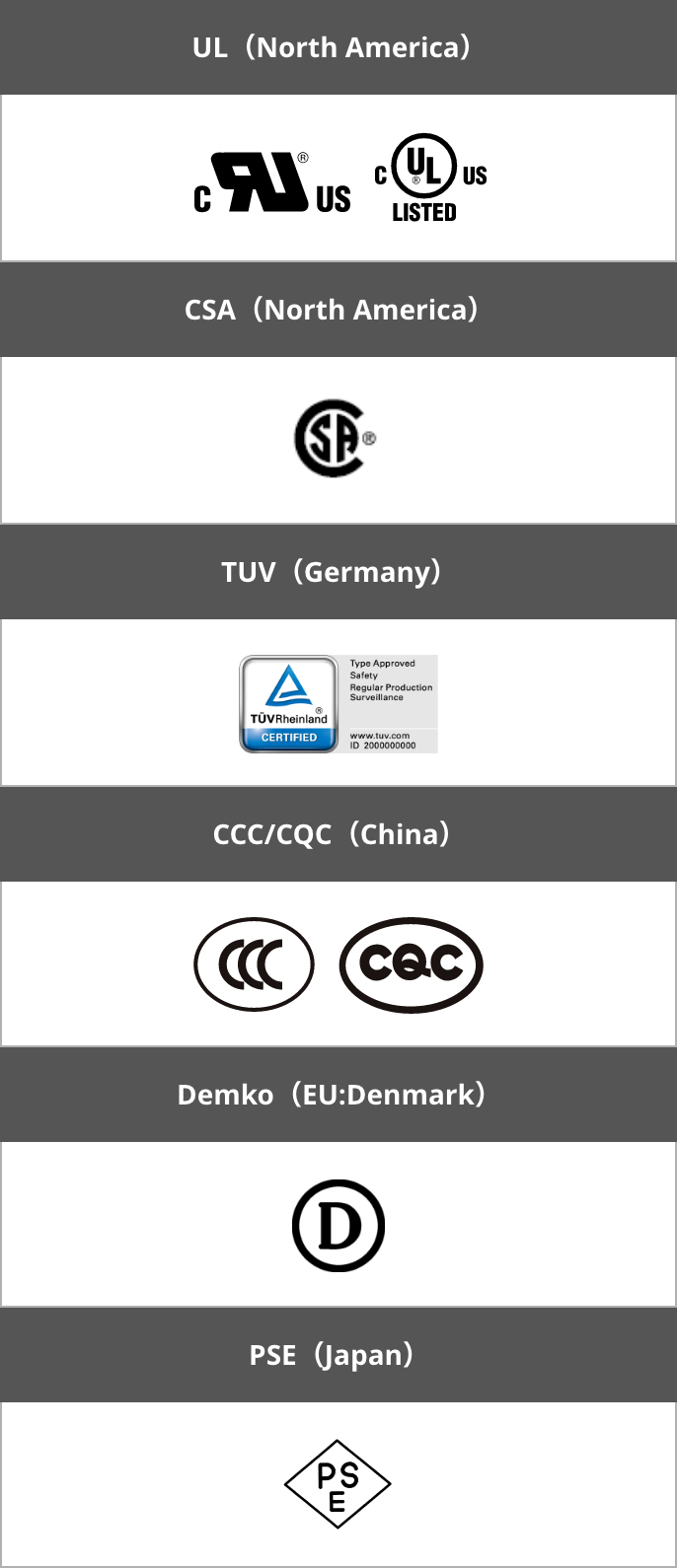

Safety standards, surveys

1. Compatible safety standards

(If you wish to obtain the safety standards for the actual equipment, we will prepare the data and documents necessary for obtaining the safety standards.)

2. Compliance with laws and regulations

Compliant with RoHS directive, conflict minerals, etc.

3. ISO

- Development

- ISO 9001 certified

- Production plant

- ISO 9001 certified, ISO 14001 certified

Features of our power supply products

(low-voltage power supplies/high-voltage power supplies)

-

- Flexible approach

- We can propose customized power supply solutions as per your requirements.

-

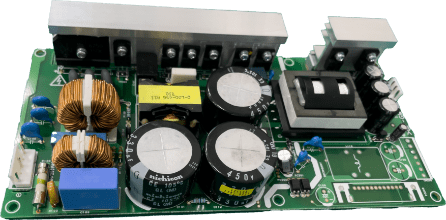

- Wide range

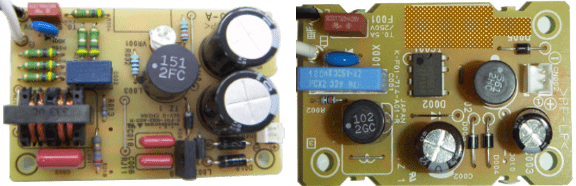

- From a few watts up to 5kW. (Please contact us for 5KW or more)

- Multi-channel support Single output/multiple output

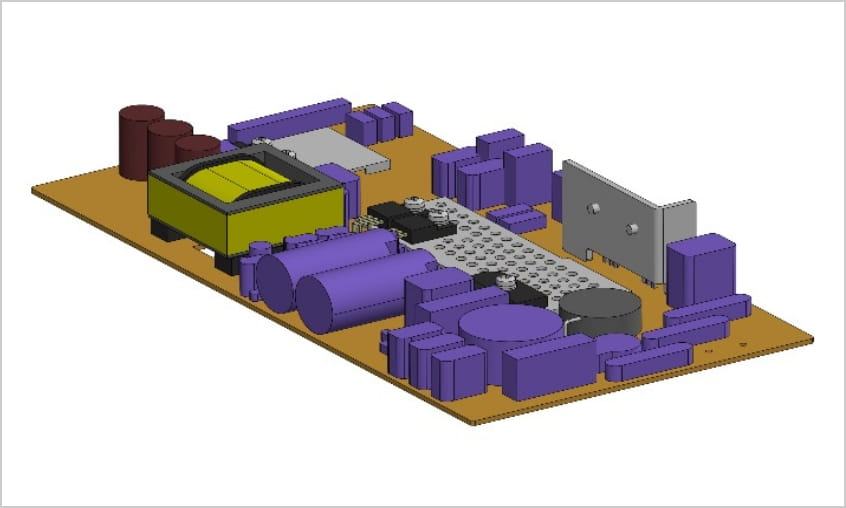

- It is possible to check the layout of parts beforehand through 3D CAD images

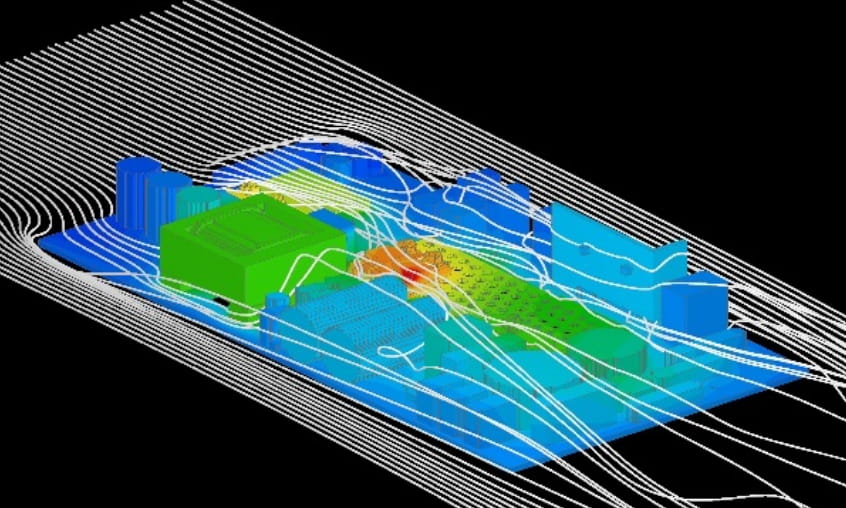

- It is possible to conduct thermal fluid analysis through simulation

- For parts such as chip products where it is difficult to mount thermocouples, it is possible to check the temperature of the parts with a thermoviewer to ensure safety

- We can handle everything from circuit design to evaluation/analysis, actual design, and mass production as per your requirements.

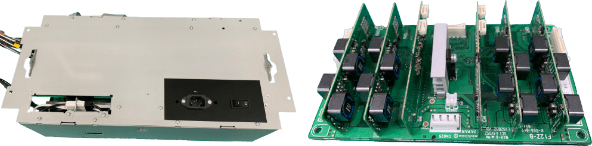

- Achieving high quality by using our proprietary automatic testing equipment

- We can support special specifications (environment resistance, wide temperature range, high voltage power supply, sequence, etc.)

- We can also handle sudden changes in your specifications

- We can also offer safety design by using over voltage-resistant capacitors.

Power supply technology

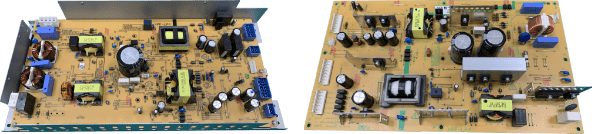

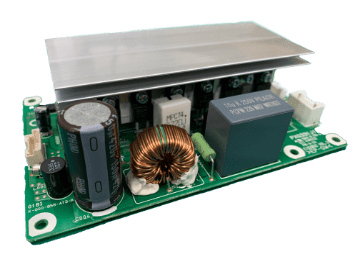

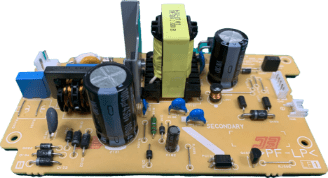

Low voltage power supplies

・Energy saving for switching power supplies

For reducing the environmental burden, with regard to office equipment that requires energy saving, it is required to supply equipment that complies with the internationally enacted energy saving system (International Energy Star Program). The standard values defined in these requirements are becoming stricter year by year. Here, Nichicon supplies products that meet these requirements.

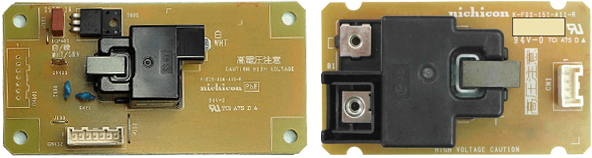

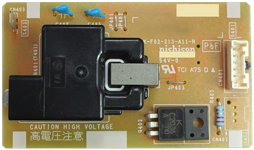

High voltage power supplies

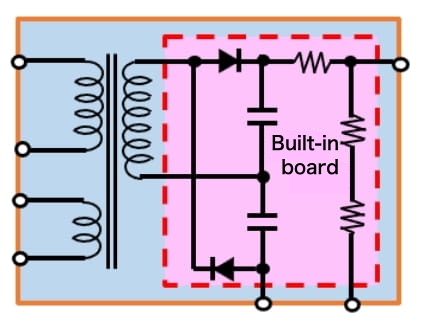

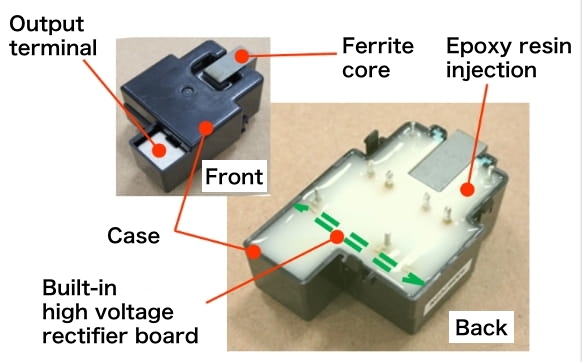

High withstand voltage insulation technology

and integrated design from transformer to high voltage power supply

Interference

and induction measures

High-voltage power supply specification range

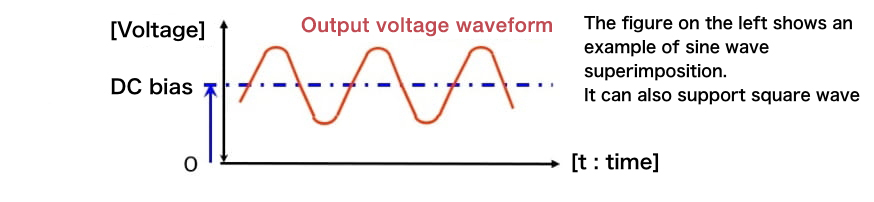

Output form

- Direct current (DC)

- +output/-output

- Alternating current (AC)

- Sine wave/square wave

- DC bias AC voltage (AC+DC)

Control method

- Direct current (DC)

- Constant voltage control/

constant current control

- Alternating current (AC)

- Frequency control/PWM control

Protection function

Over voltage protection/Overcurrent protection/Short circuit protection

External input signal control

ON/OFF control

- AC variable output

- Frequency control/PWM control: By external input signal.

- DC variable output

- Voltage (current) control: by digital or analog input signal

External output signal

Voltage monitor signal/current monitor signal

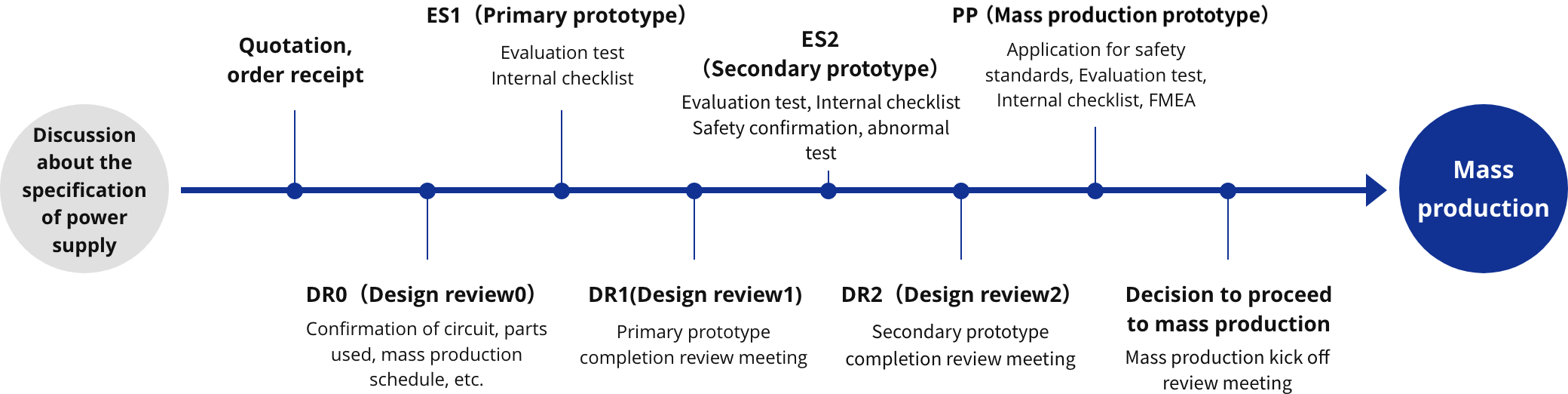

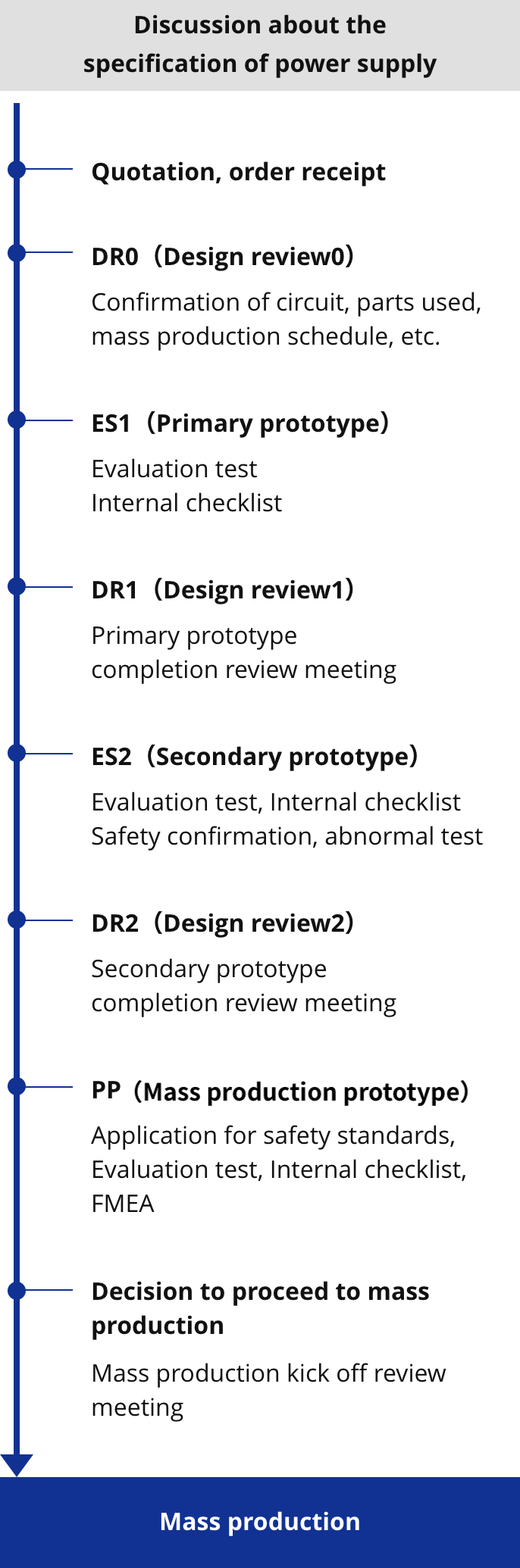

Quotation and development process

Quotation

Based on your requirement specifications, we will have a discussion with you and submit our quotation.

At the time of submitting the quotation, in addition to the mass production unit price, we will also provide the prototype cost (unit price per unit), development cost, mold cost, and safety standard certification cost (when obtaining the safety certification for the power supply only).

Flow from quotation to mass production

Development period

From six months to one year. (Differs depending on the specifications of power supply)

We can also look into the possibility of shortening the delivery time based on your requirements.

Product lineup

Air purifier

Room air-conditioner

Office equipment

LED lighting

Ultraviolet irradiation device for sterilization

Sewing machine

Industrial robot

Cinema projector / LD driver

Special applications

Other applications

- High voltage power supply for office equipment

- Communications equipment

Network

Inquiry

For questions or inquiries on general, technical or others, please contact here.