- TOP

- Products

- Film Capacitors

- Film capacitors for industrial equipment

Film capacitors for industrial equipment

We independently develop and manufacture “Smoothing Capacitors”, “Filter Capacitors”, “Snubber Capacitors” and “Charging Capacitors” for industrial equipment from the basic raw material of metalized film. in particular, our film capacitor modules used in drive inverter units have excellent high-frequency characteristics and current-withstand performance, and they are long lasting, highly reliable, and very safe. In addition, they can be flexibly adapted to meet the required shape.

Therefore, they are widely used in DC power transmission systems, factory power converters, Shinkansen drive power converters, control power supplies for industrial robots, wind and solar power generators, and various test facilities.

Features

The excellent electrical characteristics of film capacitors along with flexible appearance and terminal shapes needed for use in industrial equipment.

High frequency performance

- Sharp high frequency characteristics

(Excellent filtering effect) - Low loss, energy saving

Current withstand performance

- High ripple current capability

(High current density per unit volume)

Long Life

- More than 10 years under severe high temperature and environmental conditions maintenance free

Stable Characteristics

- Stable capacitance change with respect to temperature change

High reliability and safety performance

- Self healing type

- Comes with auto-shutdown security mechanism

Freeform shape

- Flexible external shape

(square/round) - Flexible terminal shape

Safety

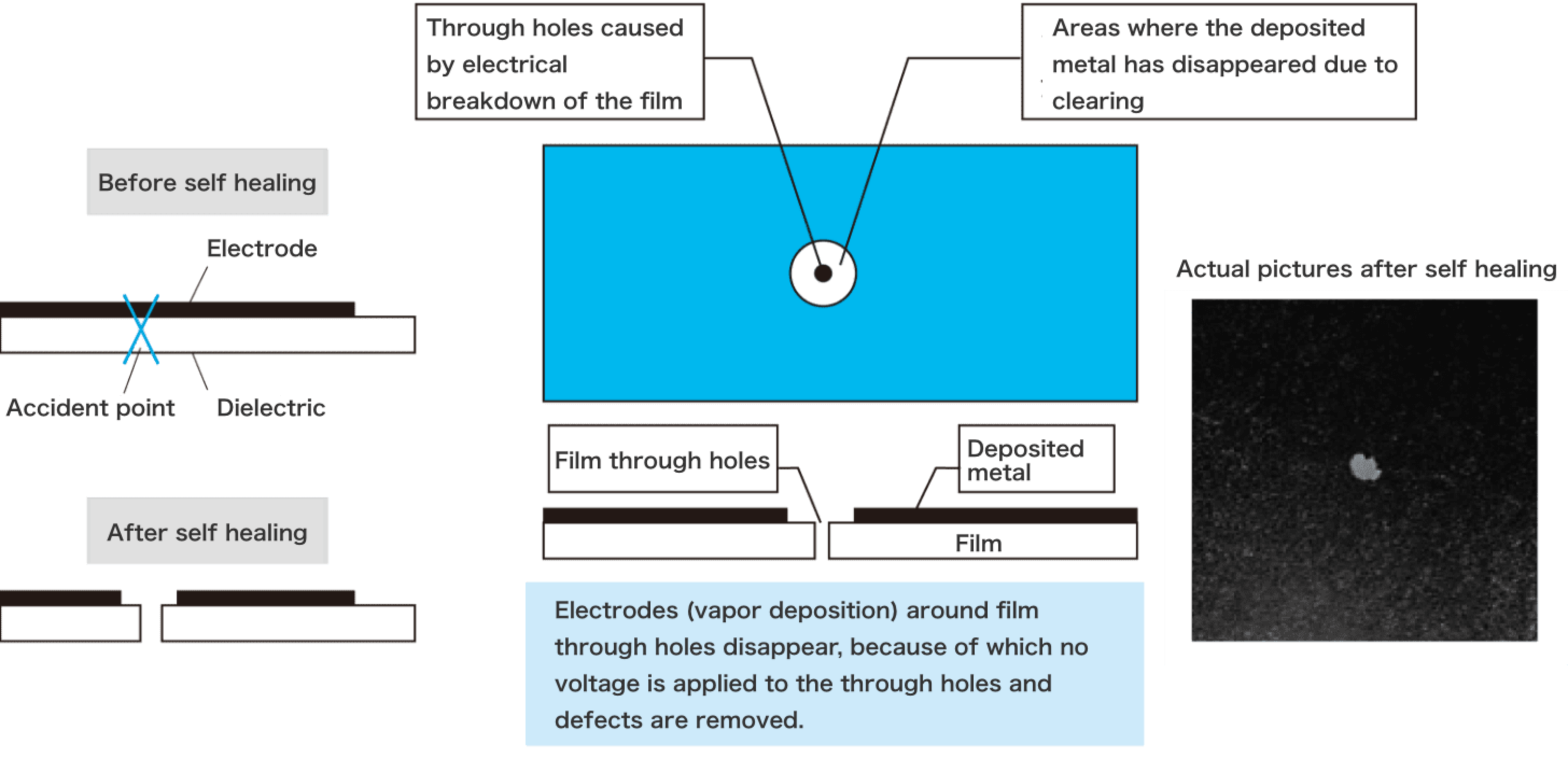

A self healing metalized film capacitor is called SH (Self Healing) capacitor.

Self-healing means that when a part of the film suffers electrical breakdown, a small minute area of the electrode adjacent to the breaking point disappears, instantly restoring the function as a capacitor.

Even if a local electrical breakdown occurs in the dielectric of SH capacitors, the insulation of the broken part recovers due to self healing performance of capacitors. However, when self-healing occurs repeatedly such as at the end of life and when damage increases, even if the self-healing function stops working, large fault current does not flow because of the resistance of the vapor deposition electrode.

However, if it is used in this state as is, the internal pressure of the case will gradually increase due to the generation of gas in the faulty part, and the case may eventually burst, leading to secondary damage.

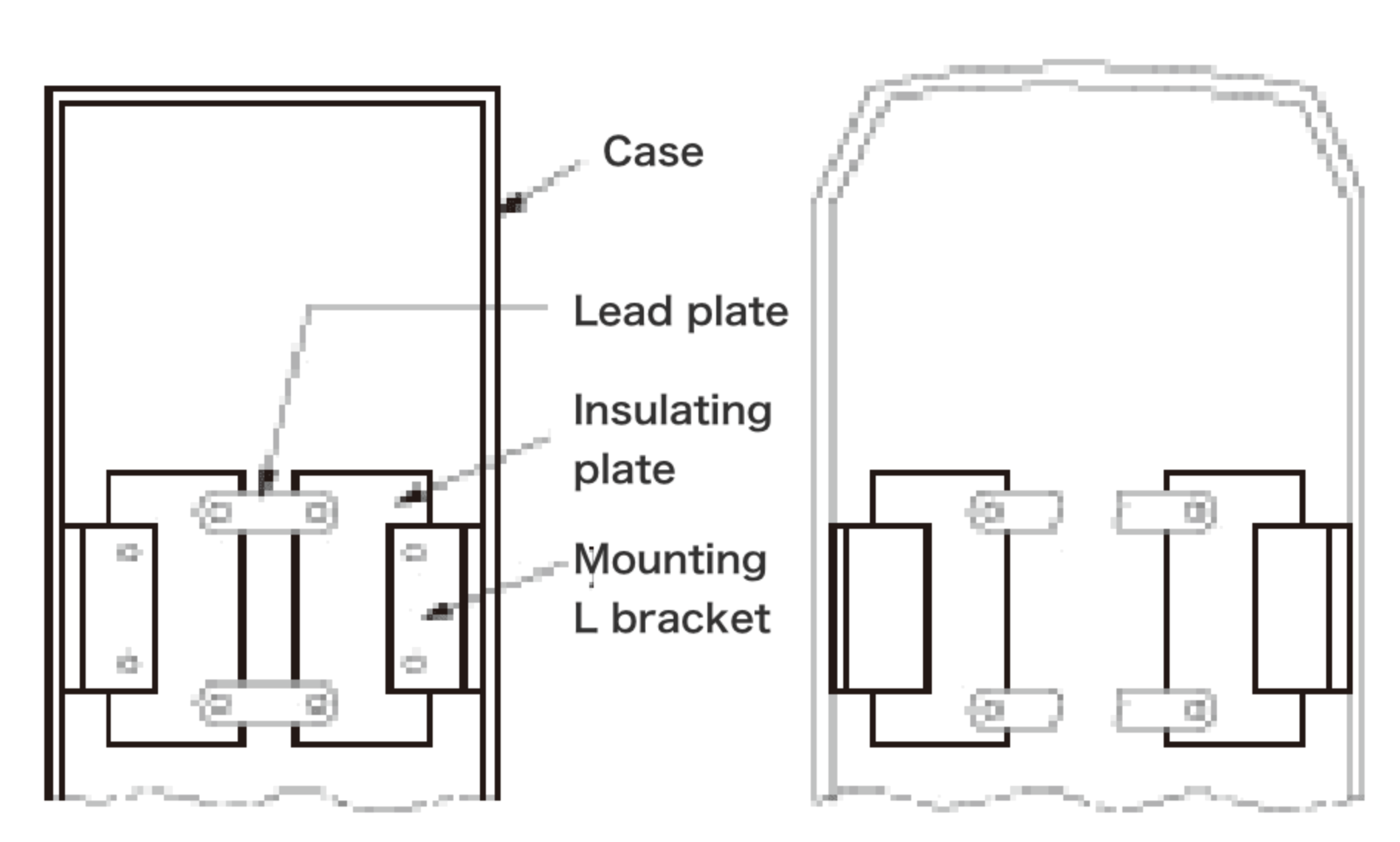

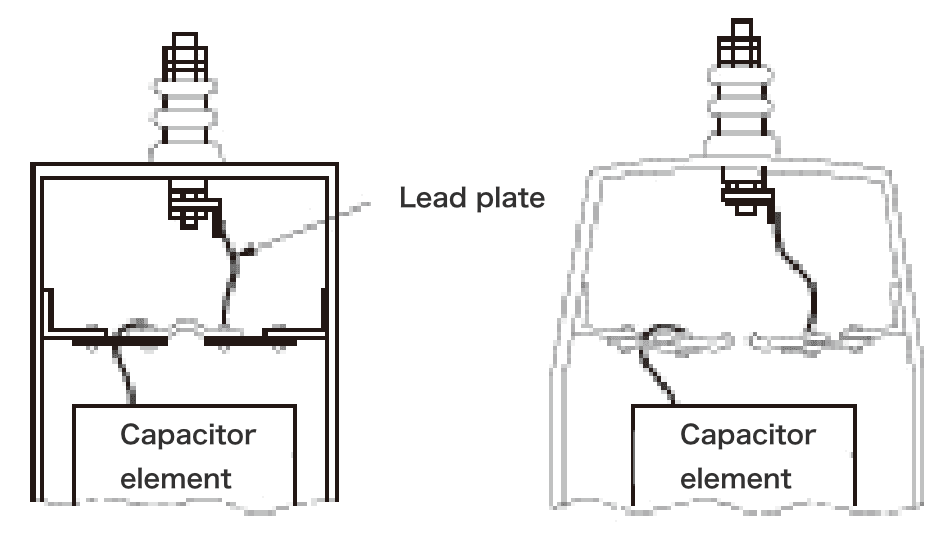

For this reason, as a protection device, we use a safety device that cuts off the current by using the deformation force of the case, or an abnormal pressure detection switch that detects increase in internal pressure, or a safety mechanism that opens the current path of the faulty area of the element.

(Please see the figure below for the structure and operating principle of safety devices and security mechanisms.)

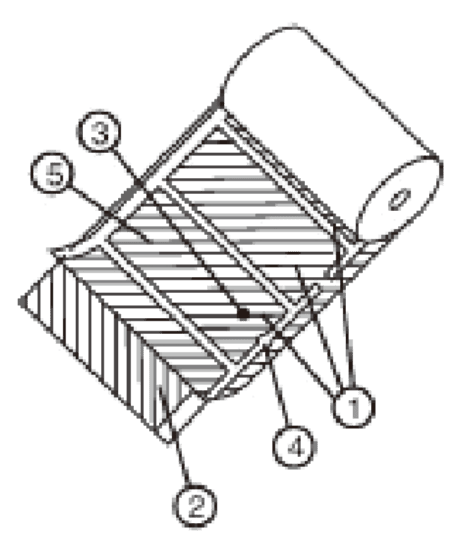

Structure and operating principle of safety devices

Method using case deformation force

Structure and operating principle of safety devices

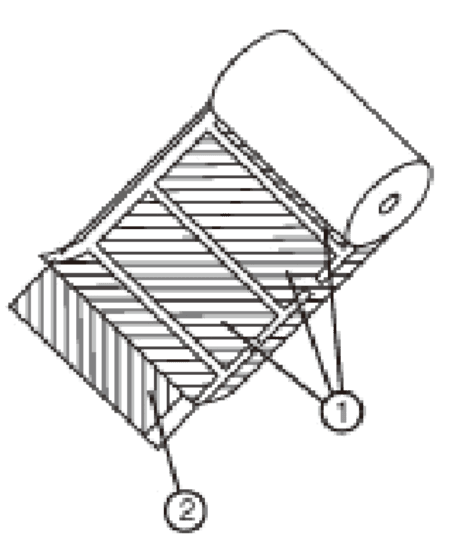

a. The state of each electrode is normal before the safety mechanism is activated.

b. The state after the safety mechanism is activated, and the state where the electrode is detached from the area where the insulation has been damaged.

- ① Dielectric of subsection electrode.

- ② Dielectric of solid side electrode.

- ③ Part where the self healing limit is exceeded and the dielectric is damaged.

- ④ Due to the overcurrent in ③, the electrode of the highest current density part disappears, because of which disconnection occurs and the faulty electrode is detached from the circuit.

- ⑤ Faulty electrode detached from the circuit.

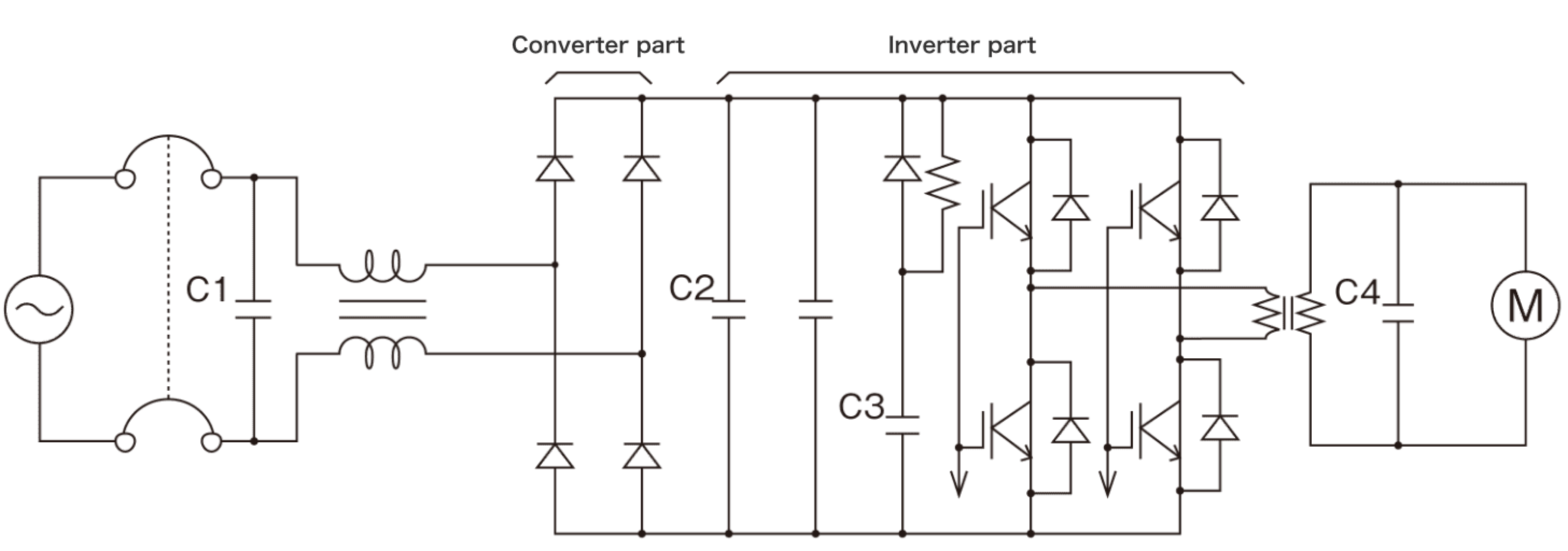

Sample Uses

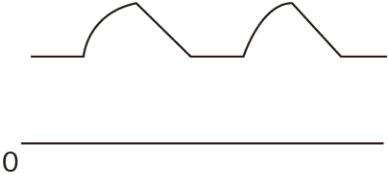

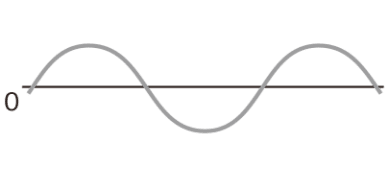

| Symbol | Applications | Applied waveform | Working |

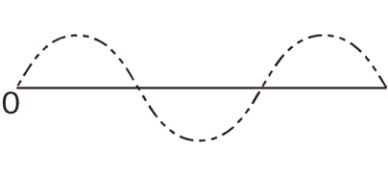

| C1 | Anti-noise capacitor |  |

Used for the purpose of absorbing noise coming from the power supply and surge voltage such as lightning, so that the distortion on the inverter side is not returned to the power supply. |

| C2 | Filter capacitor |  |

Used in circuits that convert commercial power to DC power, and it is used for the purpose of smoothing DC voltage and absorbing high-frequency ripple current. |

| C3 | Snubber capacitor |  |

It is used for protecting switching elements by absorbing and suppressing the surge voltage that occurs when converting DC voltage to AC voltage. |

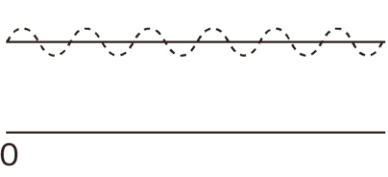

| C4 | Capacitor for AC filter |  |

Ripple voltage is superimposed on the waveform converted to AC, and this capacitor is used for removing this ripple voltage. |

Lineup

We can offer products that meet your requirements even if they are not included in the lineup below.

EJ series

| Application | For DC filter applications |

|---|---|

| Rated voltage range | 750 to 3000VDC |

| Capacitance range | 300 to 19000µF |

| Ambient temperature | -40 to +75℃ |

| Compliance with RoHS | Directive Compliant |

| Flame retardant |

|

ER series

| Application | For DC filter applications |

|---|---|

| Rated voltage range | 750 to 1500VDC |

| Capacitance range | 180 to 700µF |

| Ambient temperature | -40 to +85℃ |

| Compliance with RoHS | Directive Compliant |

| Flame retardant |

|

EB series

| Application | For AC filter applications |

|---|---|

| Rated voltage range | 240 to 480VAC |

| Capacitance range | 10 to 500μF |

| Ambient temperature | -50 to +50℃ |

| Compliance with RoHS | Directive Compliant |

EF series

| Application | For charge/discharge applications |

|---|---|

| Rated voltage range | 4000 to 20000VDC |

| Capacitance range | 150 to 3750μF |

| Ambient temperature | -10 to +50℃ |

| Compliance with RoHS | Directive Compliant |

EM series

| Application | For snubber applications |

|---|---|

| Rated voltage range | 400 to 2500VDC |

| Capacitance range | 0.1 to 13.0µF |

| Ambient temperature | -25 to +70℃ |

| Compliance with RoHS | Directive Compliant |

| Flame retardant | Resin case Filling resin Equivalent to UL94 V-0 |

QXL series

| Application | For AC power supply noise prevention applications |

|---|---|

| Rated voltage range | 125, 250VAC |

| Capacitance range | 0.01 to 1.0µF |

| Ambient temperature | -40 to +105℃ |

| Compliance with RoHS | Directive Compliant |

| Flame retardant | Flame retardant epoxy resin |

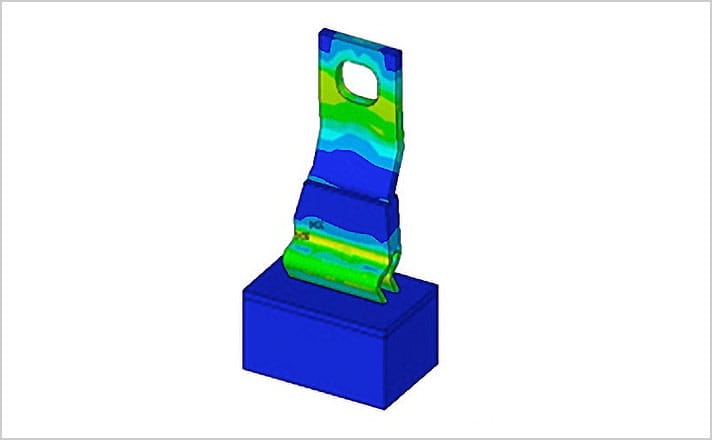

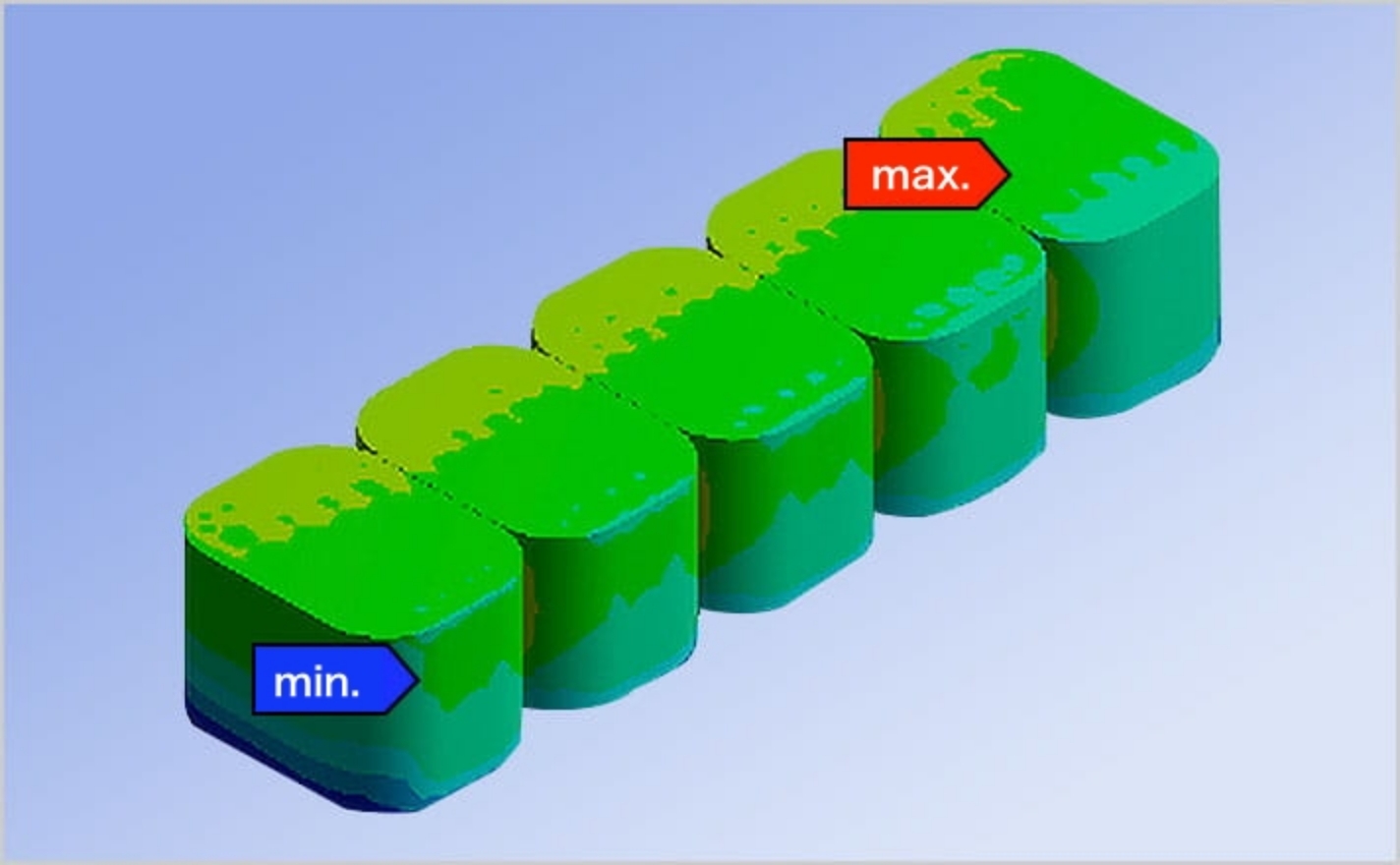

Product development by simulation

We use our own database, created based on past results, to carry out simulations such as thermal analysis, inductance analysis, and vibration analysis. With this, we increase the speed of development and reduce the number of prototypes.

Inquiry

For questions or inquiries on general, technical or others, please contact here.