- TOP

- Products

- Film Capacitors

- Film Capacitors for xEV

Film Capacitors for xEV

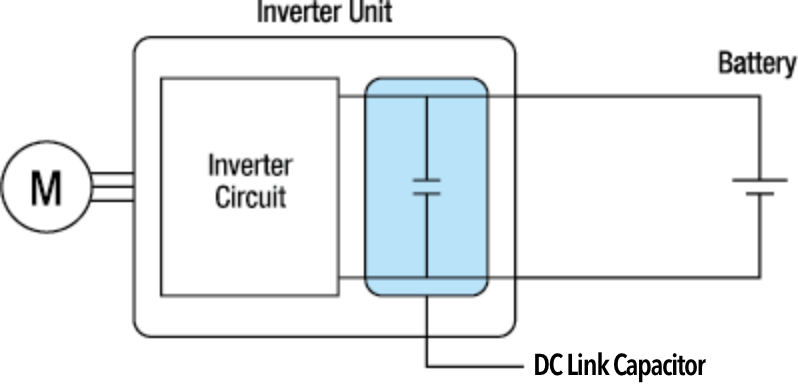

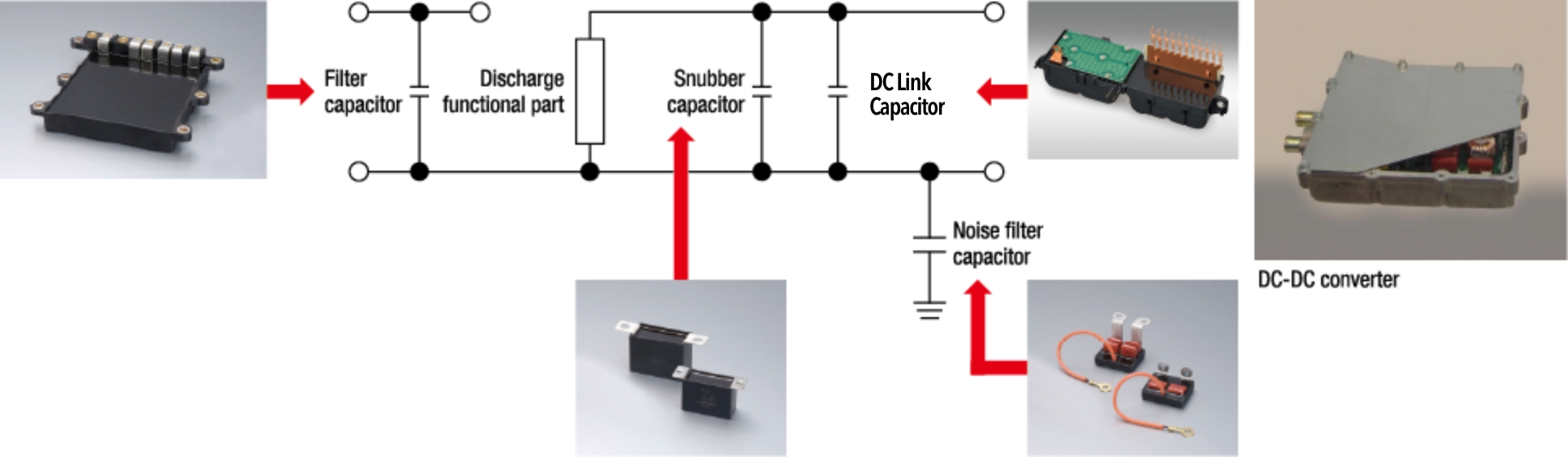

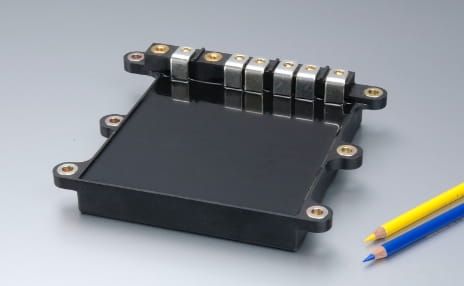

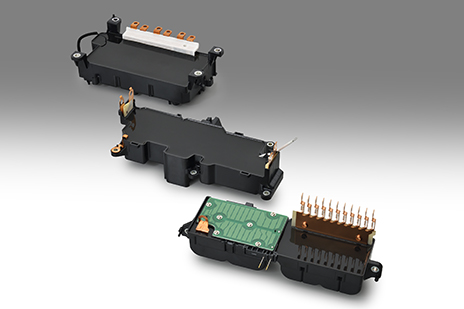

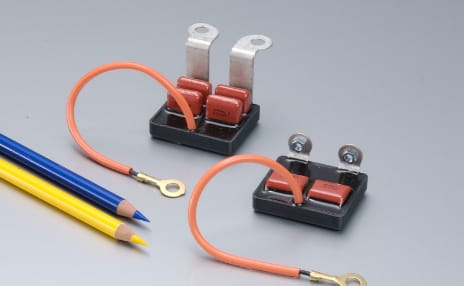

We independently develop and manufacture “DC Link Capacitors”, “Filter Capacitors”, “Snubber Capacitors” and “Noise Filter Capacitors” for xEV motor drive inverters from the basic raw material of metalized film. In particular, our film capacitor modules used in power inverter modules have excellent high-frequency characteristics and current-performance resistance, and they are long lasting, highly reliable, and very safe. In addition, they can be flexibly coinfigured to match the required shapes, and hence they are highly rated by domestic and overseas automotive companies. We are currently working on strengthening our supply system in order to meet the increasing demand of these products.

Features

The excellent electrical characteristics of film capacitors along with flexible appearance and terminal shapes needed for use in automobiles and vehicles

High-Frequency Characteristics

- Sharp high-frequency characteristics

(excellent filtering effects) - Lower loss, energy-saving

Withstand Current Characteristics

- High ripple current withstand volume

(high current density per unit volume)

Long Life

- Maintenance-free for 10 years or more even in challenging temperature conditions

High Reliability, Safety Performance

- Self-healing type

- With automatic shutoff security

Integrated Design

- Integrated design enables use for smoothing and filtering

Shape Freedom

- Flexible exterior shapes

(square, cylindrical) - Flexible terminal shapes

Safety

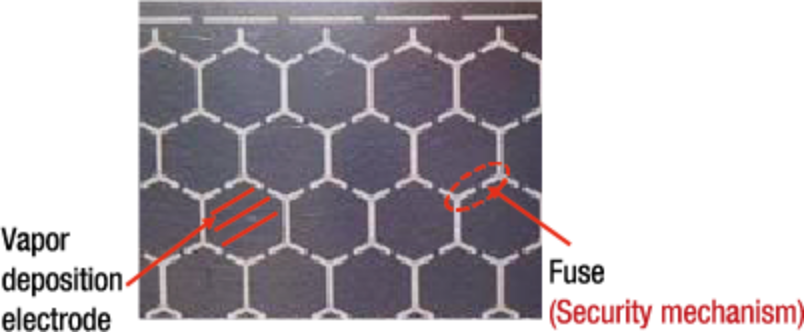

We use metalized film with safety pattern mechanisms to achieve safety and long life.

Improvement of safety by SH capacitor Pattern vapor deposition

Self-healing process of Pattern vapor deposition

Improvement of safety by Pattern vapor deposition

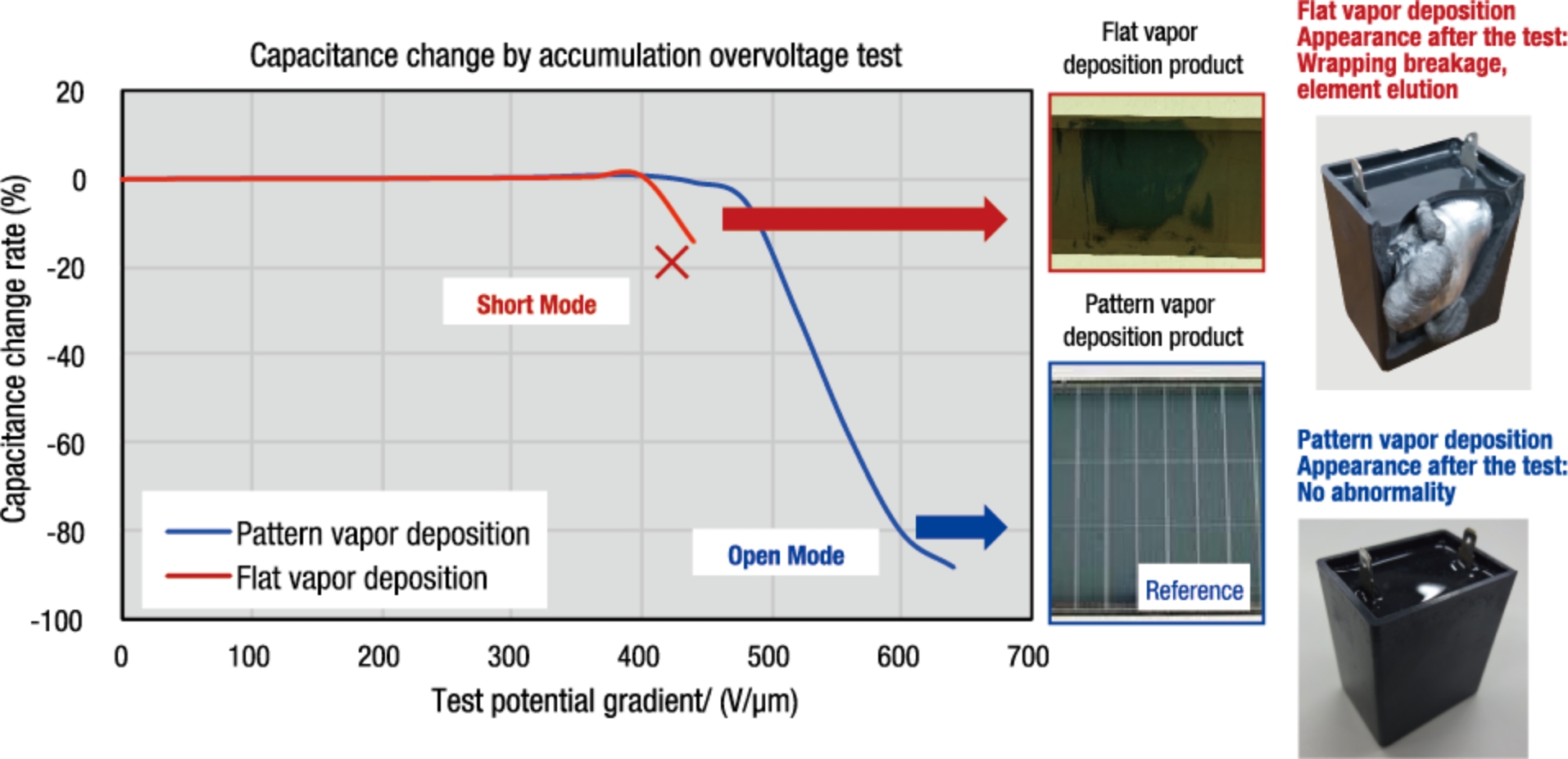

Comparison of safety between Pattern vapor deposition and Flat vapor deposition.

<Test conditions>

Ambient temperature: room temperature Voltage application time: 1 minute for each step

* In this test, the test power supply is shut off by detecting the short mode with the overcurrent, but there is a possibility of burning or fire if it is not shut off.

Sample Uses

Sample Uses for Inverter with Booster Function

Comparison of safety between Pattern vapor deposition and Flat vapor deposition.

Lineup

EM series

| Application | Snubber capacitors |

|---|---|

| Rated voltage range | 400 to 2500VDC |

| Capacitance range | 0.1 to 13.0µF |

| Ambient temperature | -25 to +70℃ |

| Compliance with RoHS | Directive Compliant |

| Flame retardant |

|

| Application | Filter capacitors |

|---|---|

| Rated voltage range | As per customer requirements |

| Capacitance range | As per customer requirements |

| Ambient temperature | As per customer requirements |

| Compliance with RoHS | Directive Compliant |

| Flame retardant |

|

| Application | DC Link Capacitors |

|---|---|

| Rated voltage range | As per customer requirements |

| Capacitance range | As per customer requirements |

| Ambient temperature | As per customer requirements |

| Compliance with RoHS | Directive Compliant |

| Flame retardant |

|

| Application | Noise filter capacitors |

|---|---|

| Rated voltage range | As per customer requirements |

| Capacitance range | As per customer requirements |

| Ambient temperature | As per customer requirements |

| Compliance with RoHS | Directive Compliant |

| Flame retardant |

|

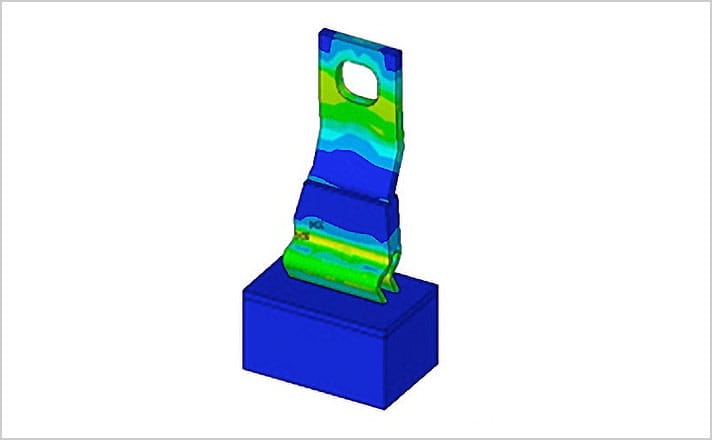

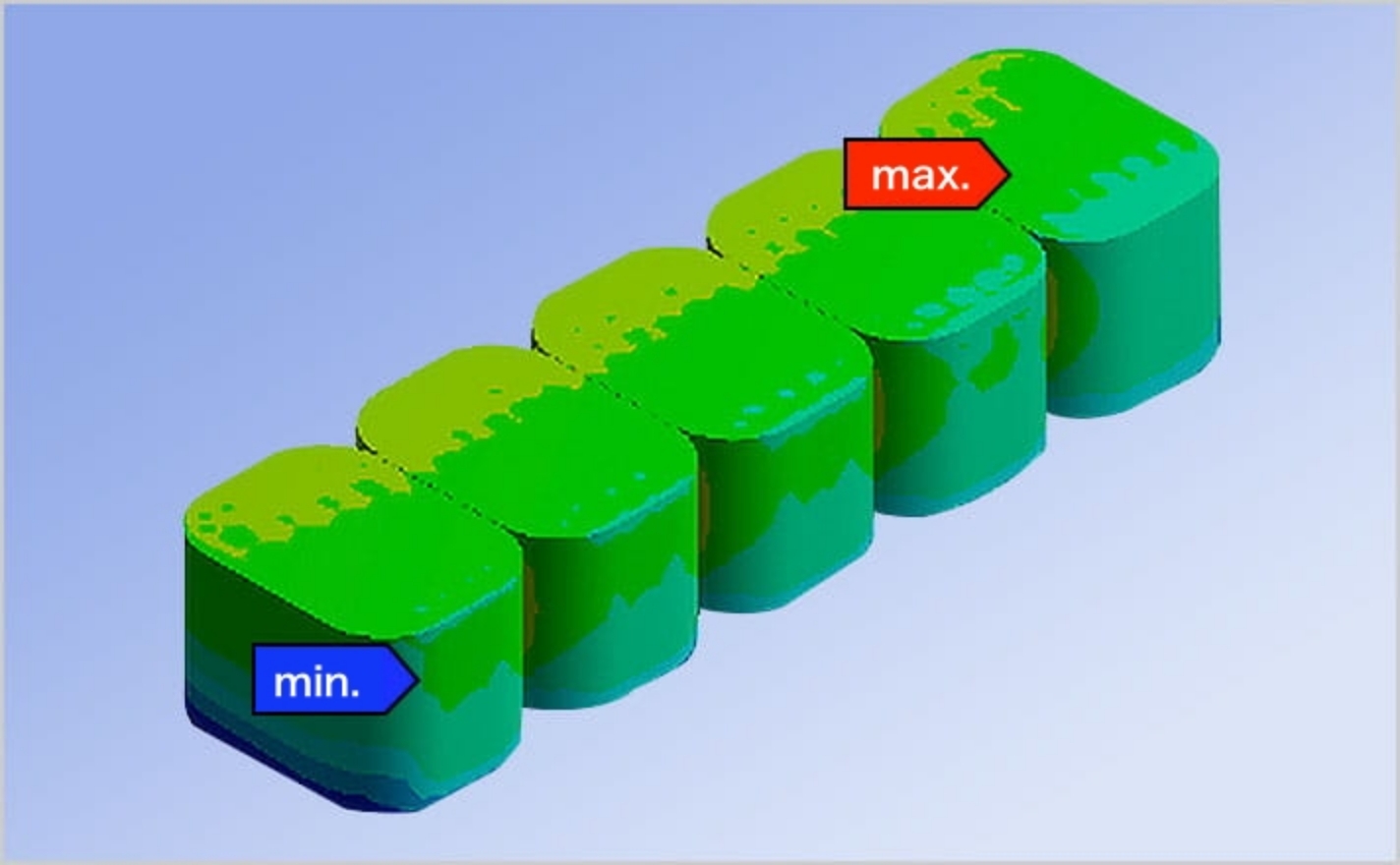

Product development by simulation

We use our own database, created based on past results, to carry out simulations such as thermal analysis, inductance analysis, and vibration analysis. With this, we increase the speed of development and reduce the number of prototypes.

Inquiry

For questions or inquiries on general, technical or others, please contact here.