In recent years, the internet of things (IoT) has been radically transforming people’s lives. A variety of products embedded with an array of sensors transmitting data are becoming indispensable for efficiently analyzing data using AI, advancing all kinds of technologies and providing notifications when an abnormality has occurred. These sensors require a power supply to operate, resulting in a demand for new storage battery devices.

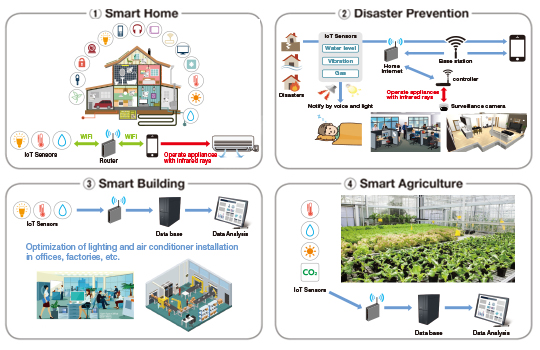

Examples of solutions using IoT are as follows. (Image 1)

1. Smart homes

IoT sensors are installed in homes collecting information such as the temperature and humidity of each room. By analyzing the distribution of temperature and humidity, air conditioning can be directed where needed to humidify or dehumidify the air, creating a comfortable living space for the occupants.

2. Disaster detection

The installation of IoT sensors in houses, buildings and near mountains and rivers enables the rapid warning of dangers using voice guidance and lights when a fire, flood or earthquake occurs. People can receive information quickly and evacuate, keeping damage to a minimum.

3. Smart factories

The installation of IoT sensors on factory lines or in warehouses enables the real time monitoring of production line operating status and inventories. This information enables production quantity adjustments and production line abnormality detection.

4. Smart agriculture

Installing IoT sensors in greenhouses to collect and analyze data on temperature humidity and light to create an optimal environment for plant growth.

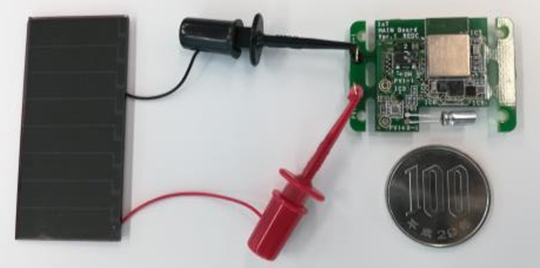

Sensors can operate anywhere when using a commercial power supply. However, in cases where a power supply is unavailable, storage devices are required. In many cases, a primary battery is used, but primary batteries have a short service life and must be replaced periodically. Switching to a rechargeable battery mounted together with an energy harvester enables the system to become self-sustaining and maintenance-free, This results in an increased demand for rechargeable batteries optimized for IoT sensor applications. One example is the environmental sensor being considered in collaboration with RICOH Electronic Devices Co., Ltd. (Image 2) Electricity generated by a solar panel is stepped down using a low energy consumption electric current step-down DC-DC converter for RICOH Electronic Devices’ energy harvester and stored in a small lithium ion rechargeable battery. By stepping down the stored energy with a low energy consumption electric current step-down DC-DC converter and driving sensors and a wireless module that can measure temperature, humidity, pressure and light, this information can be transmitted via Bluetooth for data collection. It is also equipped with an IC that monitors battery voltage, making it easy to know how much battery energy remains. Environmental sensors equipped with our SLB series 0.35 mAh (φ 3 × 7 L mm) of small lithium ion rechargeable batteries can achieve maintenance- free operation when combined with solar power generation. The SLB series is optimal for this application because it is capable of low current charging and high current discharge excellent cycle characteristics and a long service life. The internal resistance of the SLB series is lower than ordinary lithium ion rechargeable batteries allowing it to be charged using a small current. Energy harvesters generate small charging currents giving the SLB series an advantage compared with other batteries. The lower internal resistance allows for more energy to be discharged in a shorter amount of time IoT data is collected using various communication methods and the amount of power required differs depending on the amount of information and distance. This will result in increased power consumption and a larger current is required. In order to discharge with a large current, we would need to increase the product capacity, which increases the size and cost. The SLB series can generate a large current avoiding the need to make the product bigger and more costly. The SLB series can be charged and discharged thousands of times more compared with ordinary lithium ion rechargeable batteries, contributing to maintenance-free operation.

The SLB series structure and features are shown below. The basic technology is based on Toshiba Infrastructure Systems & Solutions Corporation rechargeable battery SCiBTM technology, with the added features described below. By adopting lithium titanate (LTO) for the negative electrode, the developed products have a high of rapid charge/discharge rate* (maximum 20C). They have a high input/output density that approaches electric double layer capacitors. It is also durable, capable of 25,000 charge/discharge cycles at a rate of 10C and low temperature characteristics enabling operation at -30°C. This safe, small-sized lithium ion rechargeable battery inhibits the transfer of lithium metal between the electrodes, which is a cause of short-circuiting and deterioration, with an extremely low danger of ignition smoke.

Structures and features

In general, the structure of lithium-ion rechargeable batteries is roughly divided into cylindrical, square and button shapes. The SLB series developed by NICHICON is cylindrical, based on the same basic structure as our electric double layer capacitor, consisting of positive electrodes, negative electrodes, separators, electrolytic solution and exterior materials.

The positive electrode and the negative electrode are thin metal foil coated with positive electrode material and negative electrode material. The LTO, which is the main material used for the negative electrodes, is more thermodynamic than the carbon material used in many lithium-ion rechargeable batteries. LTO is a stable noncombustible material. LTO negative electrode does not react with the electrolytic solution even in the high temperature range, this makes it unlikely for thermal runaway caused by the reaction between the negative electrode and the electrolytic solution to occur. In conditions where lithium ions are released, the LTO has a property enabling it to change states from conductive to insulation, and even if a short-circuit reaction partially occurs, it does not spread to the entire battery as the LTO surface at the short-circuited portion is insolated and the discharge reaction is suppressed. Thus, even if an internal short circuit occurs, the exothermic reaction of the battery becomes lessened.

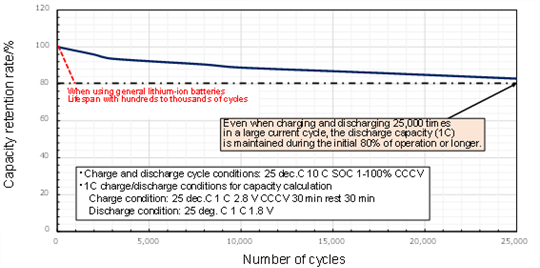

Cycle characteristics

The current rate when charging/discharging the batteries capacity in one hour is defined as 1C. General lithium-ion rechargeable battery cycle characteristics are said to be about 80% of capacity retention rate at several hundred to several thousand cycles when charging and discharging at a rate of 1C. However, the SLB series maintains a capacity of 80% or more even when charging/discharging at a ten times higher rate of 10C (1/10th hour charging or discharging) 25,000 times in a cycle test, making this a battery with excellent high-rate cycle life (25,000 cycles corresponds to the number of charges/discharges conducted seven times a day for about 10 years).

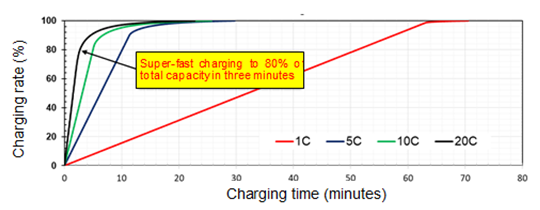

Rate characteristics

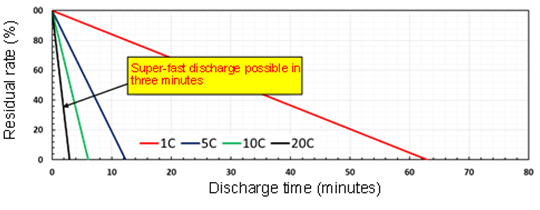

The SLB series can handle rapid charging and discharging at a maximum rate of 20C. When charging at 20C, a rapid charge to about 80% in three minutes is possible, enabling quick charging. Also, when discharging at 20C, about 95% of the capacity is discharged in three minutes, making it suited for applications requiring high power. The rate characteristics of the battery are shown in Images 4a and 4b.

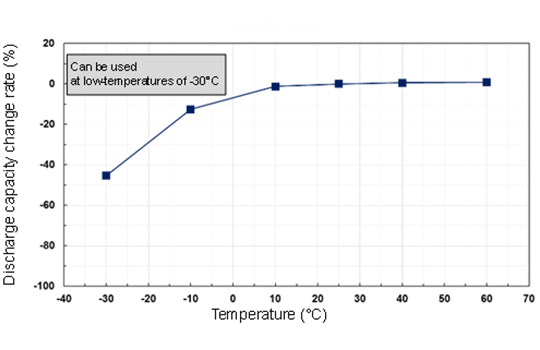

Temperature characteristics

Charging and discharging are possible even in low temperature environments of -30°C., offering excellent low-temperature characteristics. Since lithium does not migrate from the LTO negative electrode in a low-temperature environment it is safe, and even when repeatedly charged and discharged, battery performance deterioration, such as reduced capacity, does not occur. Durability in low-temperature environments is also excellent.

Safety

The safety tests in Table 1 were performed on the SLB series and it was confirmed that no rupturing or ignition occurred. The LTO negative electrode has a potential of 1.5V or more in the state of charge (SOC) range (0 to 100%), and in principle, lithium precipitation does not occur. Even in the overcharged range, the LTO negative electrode assures a potential of about 0.5V or more, and the test confirmed that lithium migration does not occur. In the unlikely event that overcharging occurs, there is no mechanism that will cause rupture or ignition, which is one of the features of this product.

| Test items | Test details | Result |

| Crushing | After a full charge, placed the vertical axis of the cylindrical battery vertically within the indenter having a radial indenter (φ10 mm) and crushed it to 50% of pre-test condition. | No rupture or ignition |

| Nail puncture | After a full charge, vertically pierced the center of the battery with a 3 mm nail at a speed of 5.5 mm/sec and left it. | No rupture or ignition |

| Blunt nail test | After a full charge, a blunt nail is pressed into the battery at a speed of 0.1 mm/sec. When battery voltage drops by 0.5 V or more, it is considered to be a short circuit and the ingress of the nail is stopped. | No rupture or ignition |

| External short circuit | Connected positive and negative terminals of the battery to an external resistor of about 1 m Ω and short-circuited it. | No rupture or ignition |

| Overcharging | Using a power supply providing 10 V or higher, the battery is charged from a discharged state at 1C (or 2 to 10C) to 250% of the rated capacity. | No rupture or ignition |

| Forced discharge | From the discharged state (SOC 0%), the battery was reverse charged at 1C for 90 minutes. | No rupture or ignition |

Future expectations

The SLB series of small lithium-ion rechargeable batteries are a product applicable not only in the IoT market, but also in a variety of other fields. NICHICON will optimize the product features in existing markets and new markets.

Note *: High-rate rapid charge/discharge performance

The current rate when charging/discharging battery capacity in one hour is defined as 1C. The ability to charge/discharge at a rate higher than 1C is referred to as high-rate high-speed charge/discharge performance.

References

1. New rechargeable battery SCiBTM offering excellent safety: Kosugi, Inagaki and Takami

2. New rechargeable battery SCiBTM for hybrid vehicle with excellent durability and safety: Takami, Kosugi and Honda

3. New rechargeable battery SCiBTM battery pack for HEV: Kosugi, Takami and Honda

4. IoT power supply-battery problems: Keiji Takeuchi

NICHICON CORPORATION

From the Dempa Shimbun, Jan. 24, 2019

[End of document]